Nanoliter Ultrasonic Pipetting

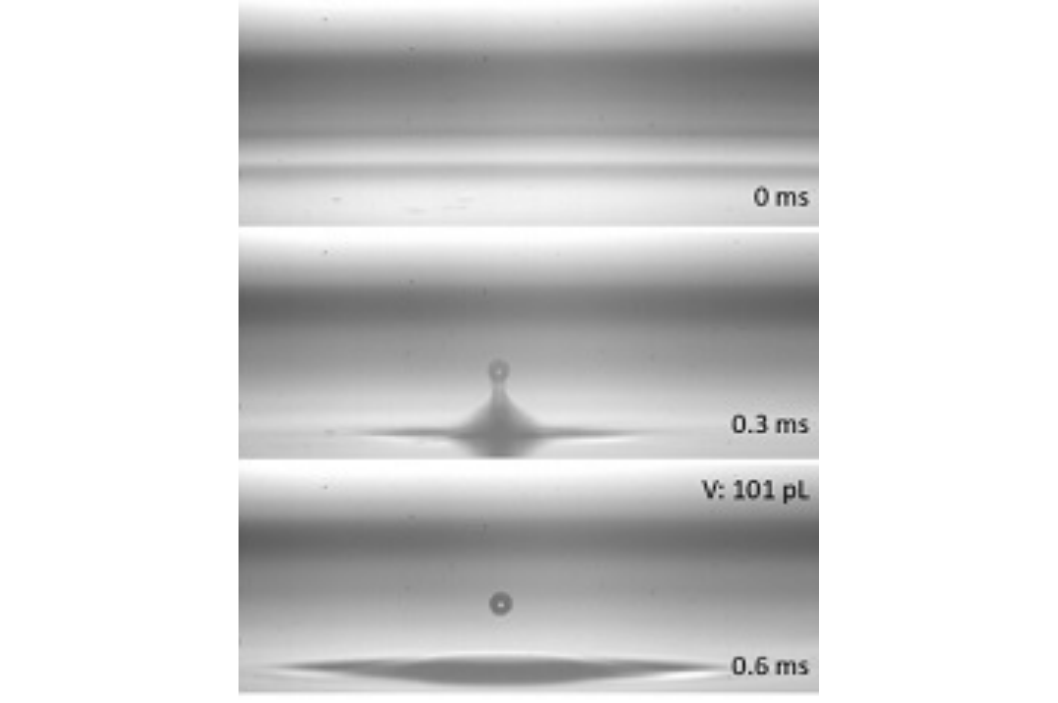

Nanoliter Ultrasonic Pipetting Technology employs acoustic waves to precisely manipulate nanoliter droplets, enabling non-contact and contamination-free micro-volume liquid transfer. This technology significantly enhances efficiency and accuracy in life science applications (e.g., single-cell analysis, genomics) and medical diagnostics, while substantially reducing reagent consumption and cross-contamination risks.

Nanoliter Ultrasonic Pipetting

Nanoliter Ultrasonic Pipetting Technology employs acoustic waves to precisely manipulate nanoliter droplets, enabling non-contact and contamination-free micro-volume liquid transfer. This technology significantly enhances efficiency and accuracy in life science applications (e.g., single-cell analysis, genomics) and medical diagnostics, while substantially reducing reagent consumption and cross-contamination risks.

Genomics Workflow Revolution |

· Ultra-Micro Volume Transfer: Achieves 2.5 nL & 25 nL precision pipetting, reducing reagent/consumable usage by >70% · Flexible Transfer: Supports user-defined transfer zones with mapped well positioning and exportable volume reports · End-to-End Automation: Integrates fully automated processes from sample preparation to post-extraction library construction, compatible with lab automation systems |

Drug Development Breakthroughs |

· CRISPR/siRNA Combinatorial Screening: Enables gradient dosing in 384-well plates · Single-Cell Screening: Facilitates whole-genome functional studies in ultra-micro volumes · Accelerated Drug Validation: Integrates fluorescence detection to optimize siRNA silencing efficiency and compound activity assessment |

Synthetic Biology Acceleration |

· Ultra-Micro Experiment Design: 2.5 nL/25 nL pipetting reduces reagent consumption 50-100x versus conventional methods · Contact-Free Operation: Eliminates sample carryover and aerosol contamination risks from tip-based pipetting · High-Throughput Capability: Enables complex reagent transfers across 384-well plates, streamlining multi-component workflows |